Welding

When I was a kid I would build projects using nuts and bolts. The projects worked out but always had a little wiggle in them. Years passed on and when I was 16 I picked up my first welding torch. This changed me forever; I fell in love with working with my hands all over again. I learned through trial and error, with some tips and tricks from a dear friend some coworkers as the years progressed.

Starting out with mig welding (GMAW, wire fed), then learning stick welding (SMAW), and then finally tig welding (GTAW). I have a strong desire to learn new things and advance my skills. Working with different alloys and metals, like food grade stainless steel to marine aluminum applications, I tend to push myself into new challenges, constantly trying to broaden my skill set. I proudly have over 20 years’ experience in welding, taking quality seriously and there are no cutting corners when executing a job -unless it’s a sharp corner ;).

Welding isn’t just a task, it’s a critical process. Knowing the importance of how to weld correctly and just welding is one of the many attributes that sets me apart from the rest!

Catering to the commercial and industrial sectors, both with in Shop and mobile capabilities. We ensure that the work is progressing in a timely and efficient manner, with no short cuts that would jeopardize the safety of our staff. The relationship that we establish with our customers ensures that they are completely satisfied with our work and that the timetables for job completion are appropriately met. This is the level of service, workmanship, and reliability that sets The Shop apart from our competition.

- Tig Welding (GTAW, ‘Heli Arc’)

- Stick Welding (SMAW)

- Mig Welding (GMAW)

- FCAW, FCAW-G

- Passivation of Stainless Steel

Stainless steel Passivation:

An effective weld cleaning solution is essential for all fabrication of stainless steel in industries that deal with construction, repair, maintenance, manufacture and production. In the past the weld cleaner task of removing welding oxidation was regarded as hazardous, time-consuming and difficult.

With advances in technology, electrolytic weld cleaning involves cleaning and passivating the metal surface by the application of strong electric currents and electrolytic fluids, in a cost-effective and fast manner. The process is also much safer when compared to the hazardous process of pickling paste application. With our system, you can also eliminate the time-consuming extra steps of surface refinishing.

Fabrication

- Custom Machine Parts

- Bucket Repair & Modification

- Aluminum Fabrication

- Steel Fabrication

- Stainless Steel Fabrication

- CAD Design

- 90 Ton Piranha Ironworker

- Track Torch

- CNC plasma table

Machining

We have a wide array of machining capabilities. From manual milling and turning to CNC we have the equipment and knowledge to machine your parts with precision.

CNC Mill- 40″ x 18″ x 18″ of travel. 20 HP 16 tool ATC

CNC Lathe- 19.5″ x 10.5″ of travel. 20 HP 12 tool Turret

CNC Plasma cutter 100 amp is capable of cutting thin gauge to 3/4″ thick plate.

CNC Torch is capable of cutting 1/2″ plate to 8″ thick plate

3D Printing 8″ cubed work envelope of 3d printing capabilities

We are able to repair metric and SAE threads.

- Thread repair; includes broken tap and or extractor removal

- Prototyping

- Custom parts, including one off

- Small batch production runs

- Smartboard tracing board

Machine Repair & Rebuild

Machines are the lifeblood of most manufacturing operations. Without high-quality machines performing at maximum efficiency, it is virtually impossible to meet tight production schedules. Machines also represent a major expense — purchasing brand-new equipment may not fit the strict budget requirements for companies that need to make every dollar count to remain competitive in today’s challenging global business climate.

Whether your machine is too large to be transported, isn’t justified logisitically, or the work is a permanently mounted piece of manufacturing equipment, we have the means and capability to come to your location or job site. We have the equipment and experience to repair your machine, returning bores back to original specs or better.

- Line Boring services up to 10″ diameter bores

- Bore welding up to 20″ diameter

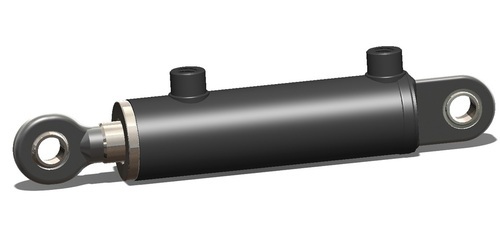

- Hydraulic Cylinder rebuild

- Worn Pin Replacement

- Grease Point Repairs

- Cutting edge replacement

- Tooth and shank replacement

Hydraulic Cylinder Repair

All hydraulic cylinders received for repair are disassembled, all components cleaned and inspected.

- Resealing of cylinders

- Rebuilding / replacing of cylinders

- Hydraulic line replacement

- Rod eye repair and replacement